Nowadays, product manufacturing needs are as varied as complex. Having worked in different industries for more than a quarter of a century, we have developed recognized experience in the manufacturing industry in general.

Manufacturer

Case study

Challenge :

Productivity and Safety

Objective :

Optimize the management and preparation of the raw material required for production.

Achievement :

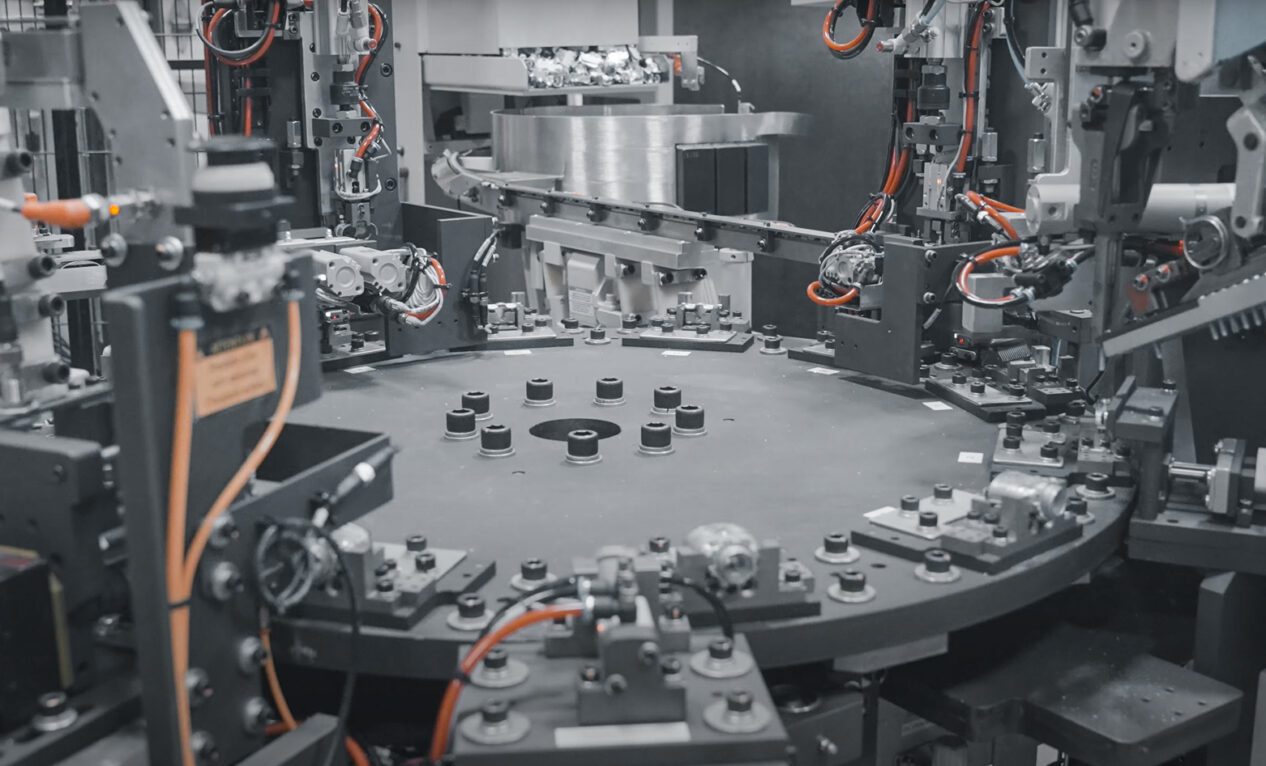

Design of a storage and handling system for cylindrical parts weighing up to 300 kg. An automatic cutting and winding system has also been developed to prepare the raw material.

Project duration :

6 months