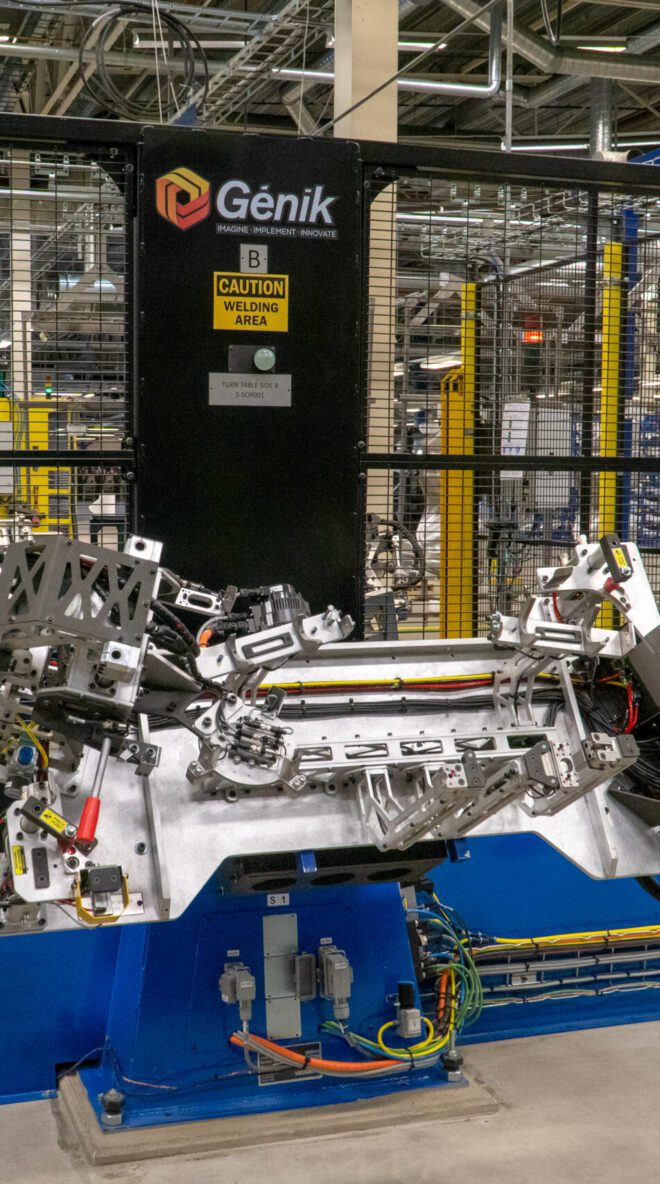

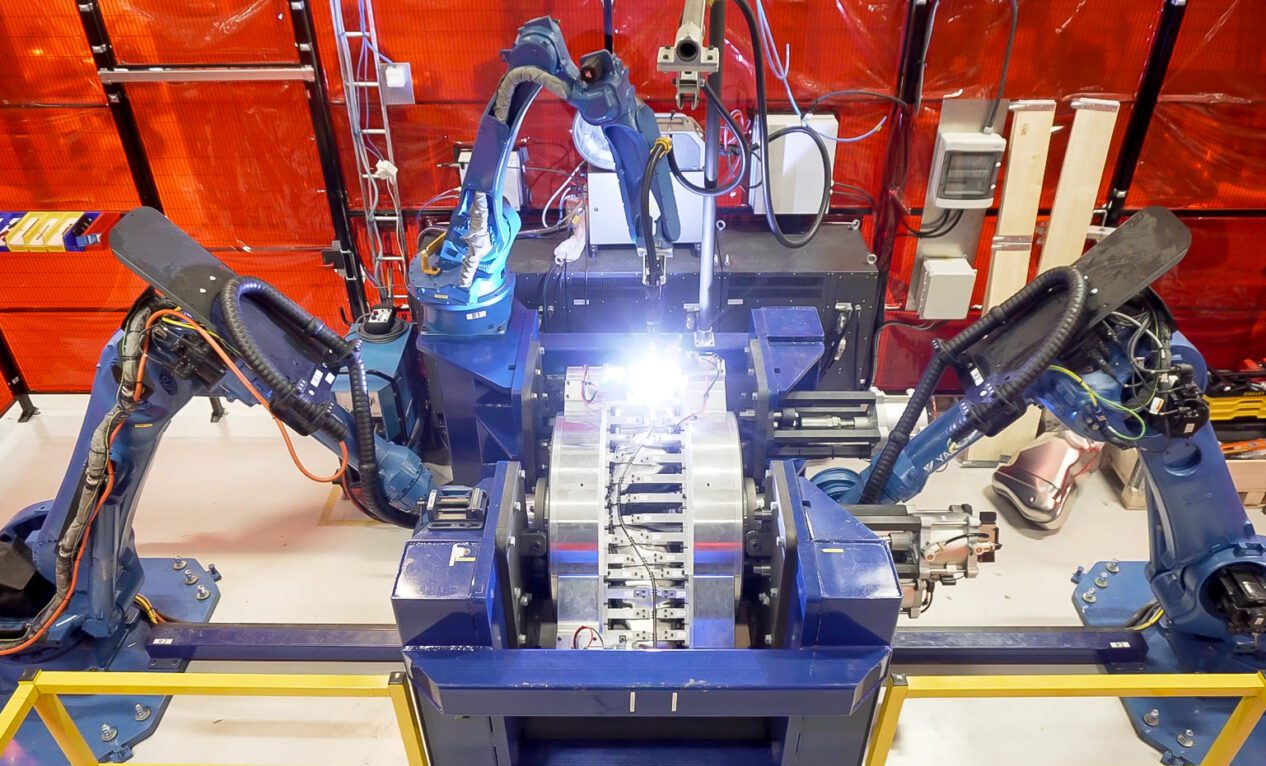

Following our expertise in the design of custom equipment, we can integrate conventional welding processes, going as far as supporting research and development for emerging fields, such as laser welding.

Welding

Case study

Challenge :

Manufacturable Product

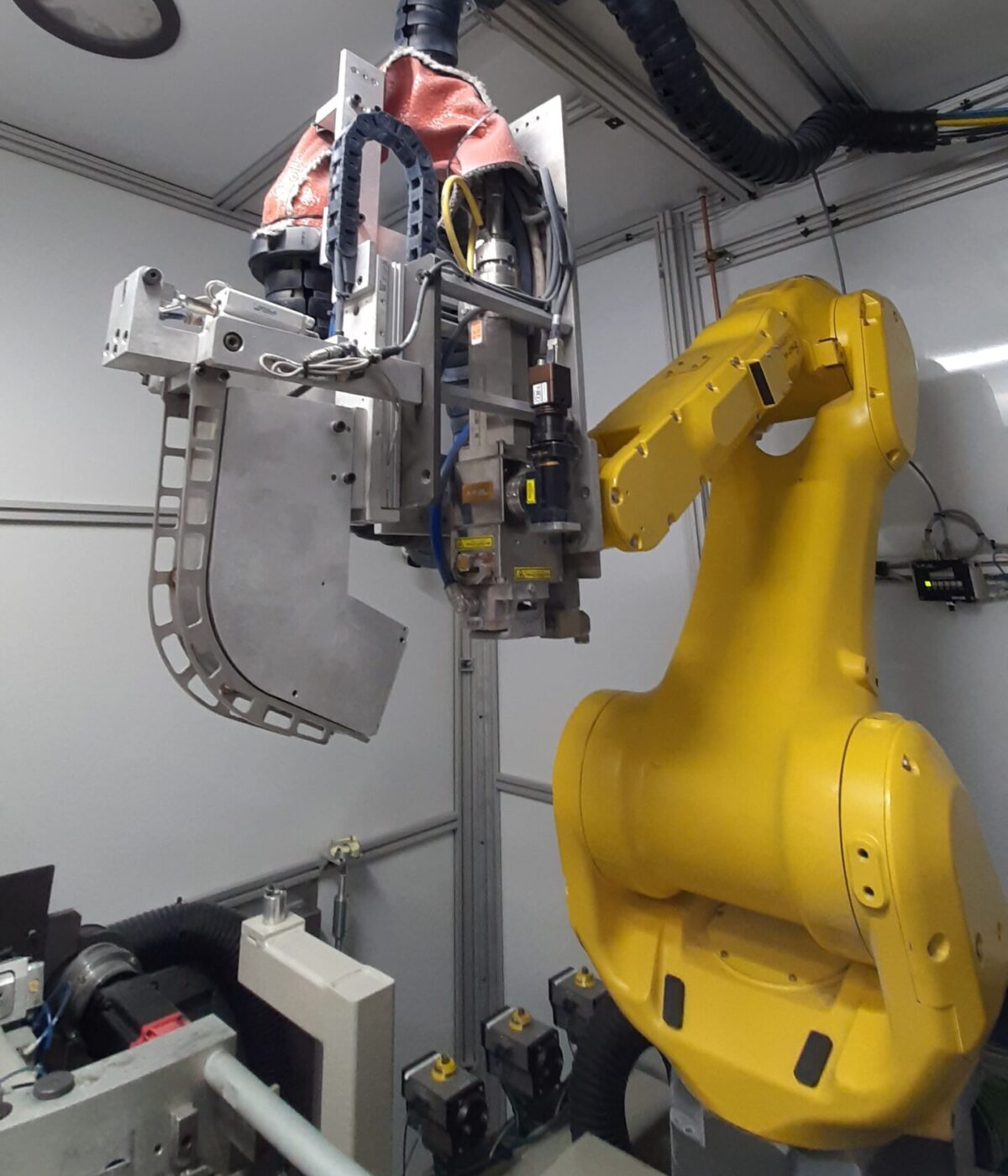

Objective :

Using laser welding, seal the assembly of an aluminum box containing active materials.

Achievement :

Since laser welding cannot be done manually, robotic equipment has been developed and optimized jointly with our client to ensure the reliability and repeatability of this new manufacturing process. To ensure quality, a micrometric inspection is performed on each product. This new equipment meets the highest safety standards in the use of lasers.

Project duration :

6 to 9 months